The Max Microchip Project- Investigating the Secrets of Implantable Pet ID

Devices

Welcome to MaxMicrochip.com. This site is dedicated to the

advancement of the technology of pet identification and recovery

through the use of implantable electronic transponders, or

microchips. These devices are being used

with

great success on a large scale in many countries, but in the US we had

a problem- several kinds of different chips in use, and no

scanner/reader device available to pet rescuers with the ability

to read all of them. (As of the date of this site's

founding, in March 2006.) To quote the readallchips.com

(apparently now moved to readallchips.org)

website,

"there is

currently no one scanner in this country that can read all

chips." I saw it as a pretty sad commentary on the state of

American ingenuity that no one in the industry could provide the pet

community with a universal microchip reading device, so I made one for

myself. And you can, too. Only basic tools are required, and you can

build it without using a soldering iron. You may make a few new friends

down at the electronics shop in the process, but that's all good. You

can

use the Max Microchip reader to

scan any stray pet that wanders into your workshop for all the common

types of microchip, although in the case of the AVID Brand "FriendChip" with encyption feature,

a substitute code is given instead of the code an AVID scanner would give.

Starting right around the same time I put the original Max Microchip homemade scanner design on the web in April of 2006, several manufacturers started making true universal four-standard scanners, and these are now becoming more common in the U.S. My scanner hasn't changed much since then; the hardware design is still the same as the original release, although as of August 2008, the software is now available as a new open-source version with Linux support.

And, new for August 2009, I have put online a web-based translator device. If you find a lost pet with an AVID FriendChip, you can type or paste the substitute code from the Max Microchip scanner here and push enter to get the chip's label code that an AVID scanner would give.

The Max Microchip scanner is

intended to be an easy-to-build project for hobby and educational use,

so its performance shouldn't be expected to be animal shelter-grade in

detection range, but it should be good enough (about 1/2 inch range) for use on calm

animals if the microchip hasn't moved far from its proper

location right under the skin of the neck/shoulders. Only basic tools are required, and you can

build it without using a soldering iron. At some point, I may

publish a more

powerful version later, but it may require parts you can't get at the

Radio Shack.

There are a few things to learn before undertaking the project. The

biggest piece of misinformation or disinformation you're likely to

find if you research these chips has to do with the so-called "125

Kilohertz and 134.2 Kilohertz microchips." If you read the Web or

other media about these chips, you're likely to arrive at an

understanding that goes something like this: "Pet

microchips are divided into two major categories, the 125 kHz and 134.2

kHz types. The 125 kHz types transmit their data at 125 kHz and

use 125 kHz technology. The 134.2 kHz types transmit their data

at 134.2 kHz and use 134.2 kHz technology. Obviously this makes

it very complicated to build a universal scanner device, because you

need to work at two different frequencies with two different

technologies which are incompatible."

The real story is more like this:

"All the

types of microchip commonly used for pets transmit their data by

modulating a continuous oscillating magnetic field provided

by the scanner device, at whatever frequency that device provides, if

it's

close enough to what the chip is tuned for. There certainly are

types of transponders/chips that by their specifications are supposed

to be tuned for one frequency or the other, but they're not so tightly

tuned that you can't read a chip at all when driving it with the

opposite frequency." Using a compromise frequency like 126 to 129 kHz

can work fine, and even if you use exactly 125 kHz to optimize

performance

with the older, and generally weaker, chip types, you can still get

good performance reading the newer 134.2 kHz types. For an

extreme test, I got a couple of chips designed for 400 kHz use. These

apparently were considered for use in pets around the late 1980's

but lately have been limited to things like salmon tracking

operations. I found that when pressed right up against a

pick-up coil operating at 125 to 128 kHz, they gave a small but useable

signal. Anyway, for

the common pet chip types, a compromise frequency works fine. Tune

your unit for something between 123 and 127 and you should be OK.

It's also helpful to learn something about two international standards,

ISO 11784 and ISO 11785. Several of the types of transponders

supported by the Max Microchip unit are types that speak one of

the

languages described by these, or a related "inverted" or

"backwards" language that is also commonly used in pet ID chips in the

U.S. Sometime you may want to peruse my separate page

for info about these ISO

standards. It describes in some detail which ISO-related

transponder types are

supported by

the Max Microchip unit, and how to interpret its output when it finds

one.

To round out the list of transponder protocols supported by the

Max Microchip reader/scanner, we have support for the rec.pets-2005a standard.

(See the full text of the rec.pets-2005a standard here)

And who wrote it? I did. (You can write an open standard

too, if you like; I wrote mine in 2005.) This standard describes a method for reading a

transponder such as the common AVID Brand "Encrypted" microchip, and

outputting

a true representation of what the chip is transmitting. Actually

it supports reading a class of transponders of which the common

"Encrypted"

microchip is expected to be a subset. "Encrypted"-type transponders

produce a unique output, called the "Primary Form" in the Standard, of

17 alphanumeric characters in length when read by a rec.pets-2005a

reader/scanner such as the Max Microchip. The standard specifies an encoding

method used to make

this primary form from what the chip transmits. The

Max Microchip reader/scanner program will also output the standard's Long Form,

which gives each chip's code as 96 characters,

which are all L's and H's. The Long Form is not very practical

for general use; it was provided for backup, in

anticipation of people who would say, "Your output is in code just like

AVID's, only different." The optional Long Form is not encoded; it's a

direct listing of what was demodulated from the chip. (If you hold the

coil in place over the transponder, the Max Microchip will repeatedly print

the Primary Form result, but will not repeat the Long Form unless there

is a change to report, such as a different transponder.

The project also includes a design for a translator machine for converting the rec.pets-2005a codes of

AVID FriendChips to the chips' label codes, but it takes an AVID scanner to build this, so it may be of less interest now that

my new web-enabled translator is available.

Construction Details for the Max Microchip scanner and Translator

Machine

If you'd like to build yourself a Max Microchip reader/scanner or

Translator Machine, first

please read my disclaimers.

All information related to these projects is provided as-is with no

warranty. The builder must take all responsibility for

determining the suitability of the information provided.

What are some examples of what the designer takes no

responsibility for? Just for example, there is no

warranty that the information or designs will be free of claims of

patent or other "intellectual property" infringement in any

country. There is no representation made that the level of escaping

radio

frequency energy will meet the legal limits of any country or

that any compliance testing has been done. (In the U.S., the

requirement that

equipment using radio frequency energy must be tested by a

recognized

laboratory may have exemptions for hobbyist projects made in small

quantities and not

built from a kit, but that determination is up to you.)

Building electronic projects, even without using a soldering iron, may

expose you to lead, a substance known to the state of California to be

harmful to your health. It's bad for you in other states

too. Wash hands after handling.

High voltages near and possibly

above the levels commonly accepted as safe to touch may appear in

the circuitry of the Max Microchip reader/scanner. Around 45 Volts

DC and 30 Volts AC is normally seen at points on the breadboard socket,

terminal strip, and dual modular outlet. It may be higher in some

cases. Suitable

protection, such as a box enclosure,

should be provided. Likewise the insulation on the main coil must

not be compromised.

The original 2006 copyrighted Max Microchip software is licensed to the public for

hobbyist, educational, and pet rescue/recovery use by individuals and

pet rescue organizations and by pet registry operators. No other

use, such as commercial product use, is permitted without specific

license. The 2008 open source version is subject to the GNU Public License.

The Max Microchip reader/scanner is not designed to be a Shelter-Grade

product. It's designed to be a lost pet's first chance for

recovery when

found by the experimenter, not a stray's last chance at the Dog

Pound. The current scanner project design produces a

tabletop

demonstration unit with pickup coil on a short tether. It is left

up to the builder how to

package it if something more portable is desired.

Read the complete instructions first, and decide if you want to alter

the design any. If you don't require this to be a no-soldering

project, you can replace the solderless breadboard socket with a blank

printed circuit board. Also, there are many types of power

switch you can choose to wire in with a soldering iron; you don't

have to

choose the miniature Frankenstein-style knife switch which hooks up

without

soldering. Actually, you may find a nice toggle switch with screw

terminals at an auto parts store you can substitute even if not

soldering. (Or you can just bypass and eliminate the switch altogether.) If your town has a cool independent electronic parts

shop, that has

resistors, capacitors, and other parts in bins, you might try taking

your parts list there. Building without soldering and using only

Radio Shack parts is not the cheapest way to build, just the most

universal.

(You may find a type of solderless breadboard socket

that has an extra connection column on each side compared to the one in

my pictures. You can ignore the extra outer connection columns if

you

get one of these, but even the close-in vertical connection columns

will be an extra tenth of an inch separated from the inner grids. This

may require forming the leads of the parts differently from

the pictures. Making the lead wires of the capacitors longer than

shown and carefully forming them as needed is OK, and may be necessary

to support the wider style of breadboard socket or capacitors

with different lead spacing.)

Parts List for the Max Microchip Reader/Scanner

- One Windows or Linux PC, reasonably up-to-date with working sound card or built-in equivalent and

with

the Max Microchip software loaded and unzipped. (New open source Windows/Linux version available Here.) (Original 2006 Beta Windows-only Software still Here) The "Preferred" or "Default"

sound card will be used if there are more than one. A 450 MHz

Pentium or equivalent should be O.K.; slower computers may still be

worth a try. Some soundcards/PCs/laptops may work better than others, but an audiophile-grade soundcard should not be necessary. Soundcards/PCs/laptops that lack a line-in audio input jack and only have a "microphone" input jack are

at a disadvantage; the microphone input generally doesn't work well with this. For use in troubleshooting, audio software such as

the free Audacity

package is useful.

- 1 count 9 Volt Alkaline Battery, fresh, Radio Shack Cat. 23-875

or

equivalent

- 1 count 9 Volt Battery Connector, Radio Shack Cat. 270-325 or

270-324 (Heavy-Duty) or

equivalent

- 1 count 25 foot 4-wire telephone cable, Radio Shack Cat.

279-336 or

equivalent. This is the standard kind of cable that would go from a

wall socket to a telephone, with kind of an oval cable cross-section. Some

special extra-flat kinds may be available, but only the ordinary kind

has been tested for the project.

- 1 count Audio Adapter, Radio Shack Cat. 274-378 or

equivalent

- 1 count Audio Cable with plug, Radio Shack Cat. 42-2449 or

equivalent

- 1 count Screw-type 4-position barrier terminal strip, Radio Shack

Cat.

274-658 or

equivalent (or the 6- or 8- position type.)

- 1 count Dual Modular Telephone Outlet, Radio Shack

Cat. 279-450 or

equivalent

- 1 count on-off switch, Radio Shack Cat. 275-1537 or equivalent

- 1 count solderless breadboard socket, Radio Shack Cat. 276-175 or

equivalent (Or the

larger Cat. 276-174 may be substituted, leaving the bottom part

unused.)

(Or, if using soldering iron

construction, the blank printed-circuit board Cat. 276-170 may be

used.)

- 4 count 10000 Ohm or "10k Ohm" 1/4 Watt resistors, Radio Shack

Cat.

271-1335

or equivalent

- 2 count 47000 Ohm or "47k Ohm" 1/4 Watt resistors, Radio Shack

Cat.

271-1342

or equivalent

- 1 count 22 Ohm 1/2 Watt resistor, Radio Shack Cat. 271-1103 or

equivalent

- 2 count 0.1 Microfarad ceramic disc Capacitors, Radio Shack Cat.

272-135 or

equivalent

- 2 count 0.01 Microfarad, 10% or better tolerance, film-type

Capacitors, Radio Shack Cat. 272-1065 or

equivalent (A single 0.005 or 0.0047 Microfarad film-type capacitor

rated 100

Volts or more can be substituted for both, if it's the right size to

fit in.)

- 1 count 100 Picofarad ceramic disc Capacitor, Radio Shack Cat.

272-123 or

equivalent

- 6 count type 1N914 or 1N4148 Diodes, Radio Shack Cat. 276-1122 or

equivalent

- 1 count type LM386 Integrated Circuit, Radio Shack Cat. 276-1731

or

equivalent

- A few feet of "22-gauge" insulated wire, solid, not stranded,

such as Radio Shack Cat. 278-1221

- Tools: Wire Cutters/Strippers, Radio Shack Cat. 640-2979 or

equivalent. Screwdrivers.

- Specimen Transponders: Ideally, at least one each of these

four: Avid

"Encrypted"

type, Avid "EUROchip", HomeAgain brand, (Here's

a source for these three.) and an ISO conformant "Full Duplex"

type. (You may be

able to get these from this

source; they call them "134.2 kHz ISO" type. Here's another

source I haven't tried yet.) (Veterinary offices may also stock one

or more varieties of transponder.) Carefully eject them from their

razor-sharp injection needles and put

the needles' safety caps back on. (Poke the needle back into the

cap as it lays on the table, without putting your hands near the sharp

part.) Then attach the transponder to a card labeled with the supplied

code sticker. It's good to have a specimen of the Trovan Technology

type also; this

site has a free sample offer! (Mine never came, but it's still worth a try.)

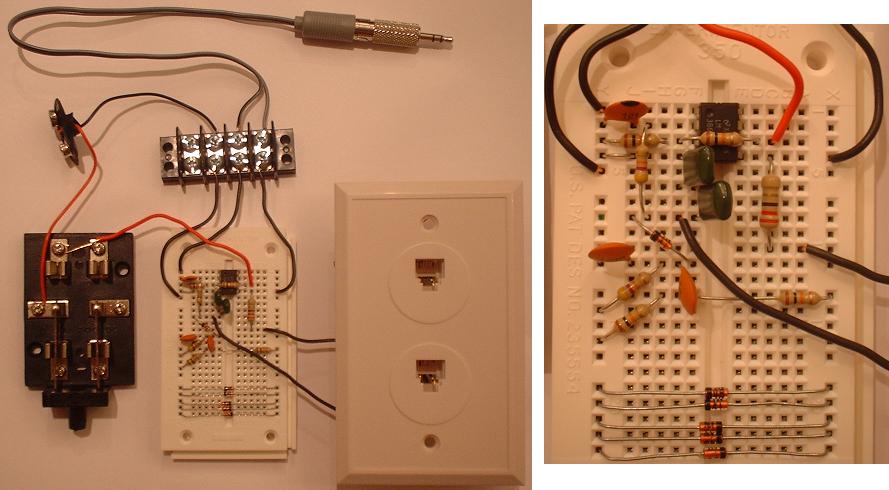

Putting it Together

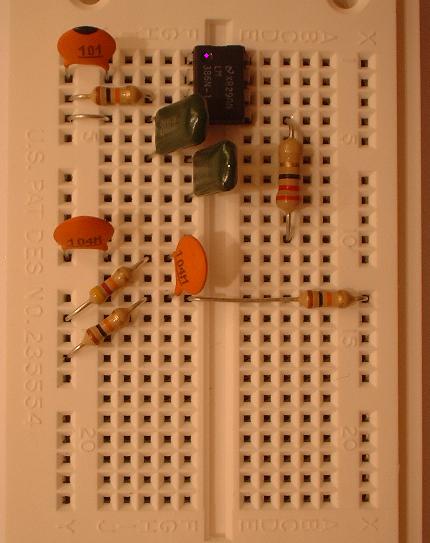

Unpack your parts. Observe the difference between the 100

Picofarad

Capacitor (probably has markings which include "100" or "101") and the

similar 0.1 Microfarad Capacitors (probably have markings which include

"0.1"

or ".1" or

"104") and cut the wire leads of all five capacitors as shown. The 0.01

Microfarad Capacitors (probably have markings which include "0.01"

or ".01" or

"103") are dark green in these pictures. Also form and cut the

wire leads on the 22 Ohm resistor

(coded Red-Red-Black-Gold.) Form and cut the wire leads on three

10000 Ohm

resistors (coded Brown-Black-Orange-Gold) and one 47000 Ohm

resistor (coded Yellow-Violet-Orange-Gold) as in the picture. Also

form and cut to size a little jumper wire section as shown at the top

left

of the picture from

one of the discarded cut off pieces.

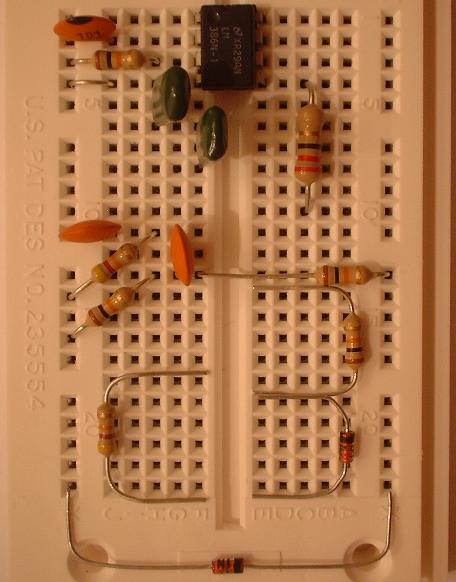

Now install all the formed parts and the little jumper wire piece as

shown

in the

picture below. Use your three formed 10000 Ohm resistors, the short,

medium,

and long one as appropriate. The 100

Picofarad

Capacitor goes up in row 2 near the top; the 0.1 Microfarad Capacitors

go farther down; and the 0.01

Microfarad Capacitors are in between, with each having one leg in row

6. Also insert the integrated circuit type

LM386. The correct top end

of the LM386 should have a notch in it, or else there should be a tiny

round indentation where the pink dot shows in the picture. This

indicates "Pin 1."

Form and cut the wire leads of one more 10000 Ohm

resistor (coded Brown-Black-Orange-Gold) and one more 47000 Ohm

resistor (coded Yellow-Violet-Orange-Gold) as in the picture below.

Carefully

separate out six of the fragile glass diodes. Straighten their wire

leads and remove all

of the sticky tape residue from the ends of the wires. Don't

leave

any. Form and cut one diode like the one at lower right in the

picture. Then

form

and cut a total of

five diodes shaped like

the one at the very bottom of the

picture. Be careful

not to

twist and put pressure on the glass part; after you bend one end of

each diode, hold the first bend

and

try to get the second bend in symmetry with the first, so you won't

have

to twist to fix it.

Now install the final two resistors; each of these has to pass over

another part you've already placed. Then put in the six diodes.

The

diodes

have little black direction bands on them. Note that of the five

diodes lined up at the bottom of the board, two have the band to the

left, and three have the band to the right. These are protection

devices for your soundcard. The other diode is

placed diagonally and has its

direction band at the top left end.

Inspect for shorts and exact wiring match with the picture

above. The socket board internally connects together the

socket holes in horizontal groups of five. It also provides

top-to-bottom connection to the separate vertical columns (of 20 holes

each) off to the

left and right. Any two component leads that can touch each other

generally are a problem unless they are connected anyway by being poked

in

the same horizontal group of five or vertical side column. Check

carefully the final two

resistors that went in for good clearance against shorts.

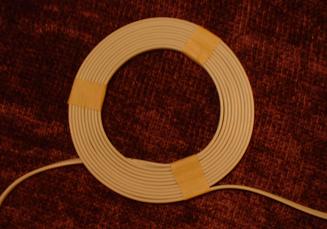

Unroll the 25-foot flat 4-wire telephone cable; straighten any

significant kinks. Now 48 inches from one end make an ink mark, and

make

another ink mark exactly 4.5 inches past that. Make a loop as in

the picture with the two marks aligned, and secure with tape over the

marks. The end going out the left of the picture is the short, 48 inch,

end; the right end will wrap around to make the coil.

Then add six more turns around the first loop, and tape it to

make a secure seven-turn flat coil.

Now 48 inches from the opposite end of the wire, make an ink mark, and

make

another ink mark exactly 10.5 inches past

that. (58.5 inches from the

end.) Make a loop as in

the picture with the two marks exactly aligned, and secure with tape

over the

marks. The end going out the left of the picture is the short, 48 inch,

end; the right end, which already has the small coil many feet along,

will wrap around to make the large coil.

Then add four more tight-fitting turns around the first loop, and tape

it in three

places as in the picture.

Then add five more turns around the first loop, and again tape in three

places as in the picture. (You can tape more often

if you like.)

The result

should be that the long flat cable now has a

large 10-turn main coil, and a small 7-turn tuning coil with some

length of cable between them. Arrange the cable as in the next picture,

but don't tape the loose wires yet.

Note that the length of the trunk

of the "Y" plus the length of the left branch should be about 46

inches, and

so should the length of the trunk plus the right branch. But the exact

total length of the cable, along with how tightly you wound the coils,

determines how much wire there is left between

the two coils, and

therefore, how long are the branches relative to the trunk. Look ahead

to see how we will use the tuning coil, and if what you've made doesn't

seem satisfactory, you may want to start over using some other length

for the measurement from the wire ends, instead of the 48 inch

guidelines suggested above. (But still use the 4.5 and 10.5 inch values for the first-turn circumferences.) When the lengths look acceptable, tape the

cables as shown in the picture. The taped pairing of the cables coming

out of the central junction point is done to keep the cables from

separating, which at any point in the wiring would have an effect

on operating frequency. Start the taping at the coils, moving toward

first the branching point and then on to the end connectors. Place the

tapes at the points where the cables

seem to want to separate.

Inspect the two ends of the cable closely, looking at the colors of the

internal tiny wires visible through the clear plastic. If the order of

the colors at the two ends is reversed for the two ends, you have what I believe is the

most commonly seen type of cable.

If your cable is like this, connect five pieces of insulated wire (with

stripped ends) to

the

dual modular

telephone outlet as shown in this picture:

There's one thick red wire connecting the Red terminals of the two

jacks, and the other two thick red wires each connect a Green terminal

with a Black terminal. Loose end wires go on the Yellow terminals. But,

if your flat cable's two ends each show an identical color order

when

held up for inspection, you'll need to wire your dual

modular

telephone outlet like this:

In either case, the requirement is to route the current that comes in

one of the loose end wires through all four of the internal wires of

the long flat cable, in order, going the same direction each time

through. Here I used red wire for the interconnections, and black wires

for the loose ends that will go to the solderless breadboard, but you

can use

any color as long as the two loose ends are solid and not stranded. You

may decide to omit the dual modular

telephone outlet entirely, cutting and soldering the individual wires

as needed

to get the equivalent connection.

Now put the audio adapter on the end of the audio cable; this is used

to

split the detected signal to both the Left and Right channels of the

soundcard. Cut off the Audio Cable at the minimum length that will

easily reach the soundcard jack. It may be worthwhile putting the

computer up on the table, to keep this short and minimize noise pickup.

(Or perhaps use a shielded audio extension between the soundcard and

the

audio adapter.) Split apart the audio cable about an inch back

from

where you have

cut it, and remove

the insulation about 1/2 inch on each of its two wires.

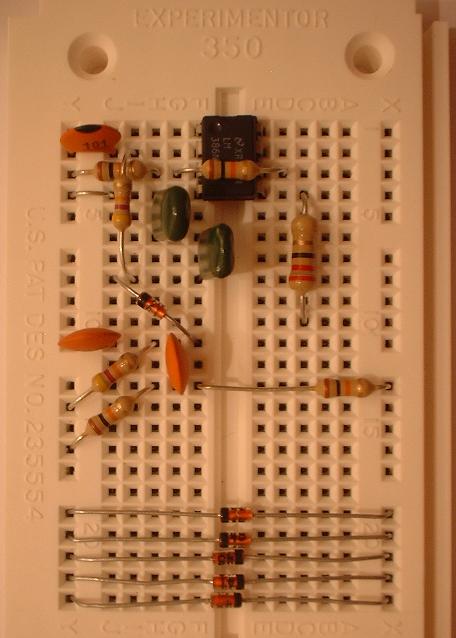

Now get out the power switch and the terminal strip, which is used to

connect the stranded wires of the battery clip and Audio Cable

to solid wires that will fit the solderless breadboard. Arrange and

connect everything as in the picture. Each of the 6 wires shown leaving

the

breadboard is made by stripping 1/2 inch of insulation off a piece of

"22-gauge" solid wire, with one end poking straight into the solderless

board and the other end hooked around the terminal screw either in the

terminal strip, the power switch, or (previously attached to) the

telephone outlet. In the picture, the solid wire from the breadboard to

the power switch is wrapped around and secured to both its top left

and top right screws; this helps keep it from coming off. Likewise

attach

the stranded wires of the battery clip and audio cable to screw

terminals as shown; red battery wire goes to the switch. Follow the

picture for

placement of the Audio cable wires; note that the Black striped one

goes

to the left column of the breadboard socket, while the unstriped one

goes to the

right column.

(If you omit the power switch, you can use the unused section of the terminal strip to replace the switch, using it to link the red battery wire to the red solid wire.)

Now secure the parts on a non-conducting surface such as

cardboard, and plug in the ends of the coil assembly. The coil

itself should be kept clear, by several

inches, of large metal objects in general, as these may affect the

operating frequency. Also avoid noise sources like CRT monitors and

power supplies including laptop power supplies. Plug the output cord

into the soundcard's

line input. This may be labeled LINE IN, or have a symbol

instead. It shouldn't have a microphone symbol on it, or a

headset symbol. It may be color-coded blue. Now comes

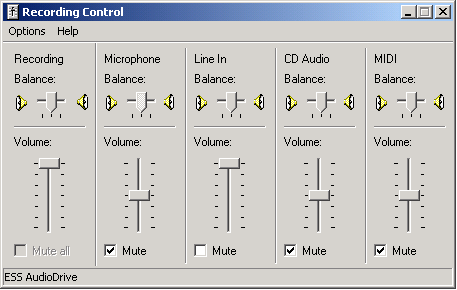

the hard part. You have to configure the soundcard to

select the line input for recording, and turn up its record

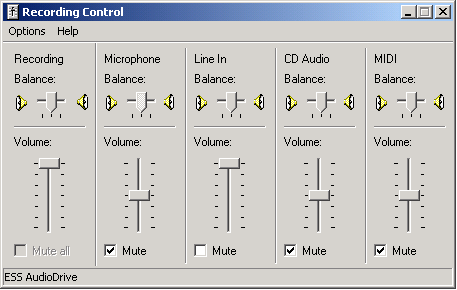

volume. Here's

one explanation of how to do this. The Recording Control

screen

may look different on different systems. Your system may have "Mute"

check boxes, meaning you have to unmute the "Line" or "Line in" control

and mute all

the others. Or it may have Select checkboxes

instead. You may have an extra master "Recording" volume control

on the left, which you should turn all the way up. (Do center

the applicable

Left/Right controls also.) Here are two examples of how the

proper Recording volume setup might look on Windows XP or earlier systems:

or

Just getting to the Recording Control screen is tricky. You have

to first get the regular volume control screen, and select "Properties"

Then in the Properties window, click on "Recording", and

make sure at least "Line" is checked. Then clicking on "OK"

should give you the "Recording Control" screen shown above.

Under Windows Vista, it will probably all look different, and under Linux, typically a mixer utility such as aumix or kmix

must be used.

Special care may be needed if you have more than one soundcard. The Max

Microchip software will use the "Preferred" or "Default" soundcard, and

the setup you do here needs to be done on the mixer which is in that

soundcard. If the

"Properties" window gives you a choice of more than one "Mixer device",

you may need to watch that carefully.

If your regular, or playback, volume control screen gives you the

option, you

may find it useful to turn up and unmute the "Line" or "Line In" volume

there

too. (As

shown above.) This may let you hear

the signals being picked up

in realtime, perhaps on your computer's internal speakers or external

ones connected to the Line Output of the soundcard. Your system

may vary.

Now study this picture indicating the main coil's sensitive

spots and the placement range for the tuning coil. The full design

tuning range is obtained by using both

the normal and flipped orientation of the small coil, and the range of

locations illustrated.

There is good sensitivity to transponders standing

vertically inside the loop, but transponders oriented in a plane

parallel to the flat coil are more realistic for an under-the-skin

chip. The orientation I would use for rating detection distances

is right under the coil below the middle green line. With

luck, your scanner should pick up the "Encrypted" type

transponders at a distance of about 1/2 inch in this orientation, which

should be enough for scanning a cooperative animal. Under good

conditions, a read may take under a third of a second, but slow,

lingering

movement of the coil bundle around the expected chip

location increases the probability of detection. ISO compliant

chips vary in read range; some may be readable at over 1.5 inches

depth. Do consider that the

red chip orientation lines in the picture above indicate near complete

invisibility at any

depth.

So what you're trying to do in scanning an

animal is, stroke the coil from front to back, trying to get the

transponder into a location equivalent to the one indicated by the

green marks in the picture. (A similar sensitivity profile

probably

applies to other round-coil microchip scanners as well, although they

may have stronger depth ability.) There is some sensitivity on the side

where the tuning coil is, possibly less, possibly slightly more, but I

would suggest using the plain side. This reference

points out

that cats and dogs chipped in continental Europe may have the chip

placed differently from the between-the-shoulder-blades position used

elsewhere.

But first it's time to test and tune. Put in the battery, turn on

the switch, and double click on the "max.exe" program on Windows or execute the file "max-lin" in a shell window on Linux. Tape in place a

transponder in one of the green orientations. For a good strong test

signal, use an

ISO conformant "Full Duplex"

type transponder if available, otherwise, whatever you have. If it's

working right, you should

see results on the screen at some point in the tuning range. With luck

you should see something like one of these four lines:

Inv. ISO 11785 A.2.1 "Destron (FECAVA version)

technology": 46781B102A

(126265)

rec.pets-2005a: 9MTR 43ZF G6L7 X79D

2

(126265)

ISO 11785 6.1 "Full duplex system": 0985

120027629061

(1,8000,126071)

ISO 11785 A.2.3 "Trovan technology":

0001BE32F8

(127137)

Here the number in parentheses, or the last number of the list of

values in the parentheses, is an estimate of the oscillator frequency,

made from analyzing the

timing of the waveform transmitted by the

transponder. The target for tuning is 125000, the closer the

better. The finished

coil configuration is whatever it takes to get the right frequency

reading. I would hope you can at least get it between 123000

and 127000; tape the tuning coil to the main coil when you get it

closest. If you don't have any

loose

specimen transponders at all, you can try tuning to maximize

interference in a

nearby AM radio tuned to 630 Kilohertz. (That's what is called the

"fifth harmonic" of 126 KHz.)

If the code result you get is a rec.pets-2005a reading, my new on-line translator machine should give you the AVID FriendChip's label code, if you type or paste it here and push enter.

Here's a Schematic Diagram

of the scanner

hardware.

Eventually, I hope to have an additional section on what to do if it

doesn't work. For now, here are some ideas:

Ask someone else to check your work.

If you made part substitutions, consider going back to the specified

types, especially the capacitors.

If you can't read any transponders at all, try connecting an audio

source to the soundcard's line input, without rebooting the computer

or changing anything. Record and play back a .WAV file from music

containing some quiet

passages, using Windows Sound Recorder or the free Audacity

package. If your system can't record soft music without distortion,

it's going to have problems with the faint signals that will come from

a tiny transmitter.

Use an Ohmmeter or continuity tester to verify the conductance path

between the loose end wires of the dual outlet assembly, with the coiled cables

plugged in. Disconnect one end of one of the three interconnect wires (red wires in the pictures),

and check the full conductance path again. Then reconnect the wire. Do

this also for the other two interconnect wires. If you saw conductance

with one wire removed in any case, something's wrong; that wire wasn't

really part of the conductance path! This means you need to trace out

the whole path again.

Not all soundcards will work equally well. Even a poor quality

soundcard should be able to detect the ISO conformant "Full Duplex"

type transponders, because of their relatively loud

transmissions. If you have your speakers active for signals appearing

at the Line In jack, it may seem like the other types have no signal at

all in comparison, because they give a fainter, high-pitched squeak.

(And the "Trovan Technology" types sound different still.) If you can't make your

speakers directly active for the Line In jack, you may need to record

and then play back to hear what's going on.

If some detection is possible but the desired frequency is unreachable,

you might try a different set of 0.01 Microfarad capacitors, or redoing

the

main coil. A couple of tenths of an inch reduction in the circumference

measurement should give a noticeable increase in frequency; increase

coil size for lower frequency.

While the starting position for the left/right controls in the

Recording Control panel should be center position, you may find that

one extreme works better. You can also try using the Microphone

input of the soundcard if you want, adjusting the Recording

Control configuration as appropriate. Generally this works poorer than the line-in jack. In some cases you may only have a microphone input.

If you'd like to share your experiences in building the Max Microchip

scanner or translator, please post to the rec.pets

newsgroup, placing the word "max" in your subject line! Have fun, and

remember to test before each use.

Parts List for the Max Microchip Translator Machine

- One Windows PC with the "xam.exe" program and "xam.bat" batch

file supplied with the Max

Microchip software, same PC description as

for the

Reader/Scanner except Linux is not currently supported and we don't care what kind of inputs the soundcard has.

- 1 count 3300 Ohm resistor, Radio Shack Cat. 271-1328

or equivalent

- 1 count type 1N914 or 1N4148 Diode, Radio Shack Cat. 276-1122 or

equivalent

- 1 count Audio cable with plug, Radio Shack Cat. 42-2449 or

equivalent

- 1 count Audio Adapter, Radio Shack Cat. 274-369 or

equivalent

- 1 count screw-type 8-position barrier terminal strip, Radio Shack

Cat.

274-670 or

equivalent (This is pictured; or use the 4 or 6 position type,

whichever)

- 4 ft. insulated wire left over from Scanner

project.

- 1 count "Encrypted" microchip scanner, with battery. "Avid

MiniTracker" recommended. Not available at Radio Shack; try this source.

I designed the Max Microchip Translator Machine as a complement to the Max Microchip Homemade scanner. It was designed to be used by chip registry operations that register AVID chips, allowing them to accept found pet reports from scanners that don't have the AVID decoder algorithm in them. (Such as the Max Microchip scanner.) Now that I've put a public access translator machine on the web, they don't need to have one of their own, but it still may serve an illustrative purpose.

To make the translator, we use a different Audio Adapter than

used in the Scanner. This one plugs into the Line Out jack of the

soundcard, which may have a headset symbol, or be color-coded Green. If

you use an adapter like the one

specified for the Scanner, you would be shorting the

two output stereo channels together, which might work but which

I wouldn't recommend. This time the Audio

Cable can be cut at any length you choose, or left at full

length. Build the unit as shown in the picture

below; there are 6 turns of insulated wire, sized by wrapping around

the "Encrypted" microchip scanner's width, and then positioned around

its top left corner. This coil connects directly to the

left or right channel output of the soundcard, passing through the

resistor and diode on the way. Although the picture doesn't show

it very well, the resistor is coded Orange-Orange-Red-Gold. The

diode is on the left; its direction is

non-critical.

PC setup for the Translator involves turning up and unmuting as needed

the main and "Wave" volume control sliders of the PC's regular playback

Volume Control panel. It's also good to turn down or mute all the other

sliders. (And center the

Left/Right controls.)

Double-Click the "xam.bat" batch file, and enter the code "86PL B8W9

YW3L

39TX Y" (translates as "AVID*089*011*053") for testing. The translator

accepts the rec.pets-2005a

Primary Form (17 characters) or Long Form (96 characters, provided for

completeness) as input for

translating,

and will transmit for several seconds

each entered code. Immediately afterwards, it will send a code which

translates as "AVID*089*299*868" for one second, at

slightly lower volume. Seeing

this

code on the display, exact in all digits, indicates a

"non-translatable" result

from the

translation process, but also confirms that the translator hardware is

working. Erroneous input, such as a transcription error in a

found pet report, is the most likely

cause of this. You might want to put a label near the display window with the legend

"AVID*089*299*868 = non-translatable" as a reminder of this. (This code won't be a real pet's ID, of course; this is one of my specimen chips.)

The "xam.bat" batch file has only one statement in it; it just runs

"xam.exe" for you. You can just double-click "xam.exe" instead, but I

have found that the "paste" operation, through use of the right mouse

button, only works if the batch file is used. Your system may be

different. For the batch file to work, it needs to be outside of any zip

file folder, with "xam.exe" in the same folder. In order to leave the

"Avid

MiniTracker" turned on continuously, a quality battery eliminator is

desirable.

Once again, if you'd like to share your experiences in building the Max

Microchip scanner or translator, please post to the rec.pets

newsgroup, placing the word "max" in your subject line!

Thanks,

Andy Kluck, Max Microchip designer. (E-mail postmaster nospam.maxmicrochip.com; leave in the nospam part!)

nospam.maxmicrochip.com; leave in the nospam part!)

-------------------------------------------------------------------------

or

or

nospam.maxmicrochip.com; leave in the nospam part!)

nospam.maxmicrochip.com; leave in the nospam part!)